Small Diameter Gravity Sewers

Sewers

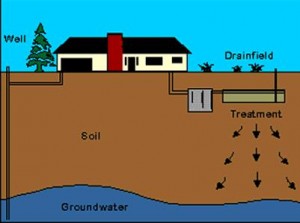

Small diameter gravity sewerage (SDGS) also known as settled sewerage and solid free sewerage, is a system for conveying domestic wastewater which has been settled in a septic tank (referred to interceptor tank) . It was developed in Zambia in 1960, to remove the settled wastewater from aqua-privy tanks. Several schemes were implemented near Lusaka and in the Copperbelt.

Following its successful functioning in Zambia, SDGS was then installed in the following countries:

- Australia, in 1962;

- Nigeria, in 1965;

- United States, in 1975;

- Colombia in 1982;

- Brazil, in 1987; and

- south Africa, in 1989.

It is now most common in Australia and the United States, with over 300 schemes installed. The CPHEEO Manual on Sewerage and Sewage Treatment (Second Edition, 1993) discusses this system as small bore sewer system.

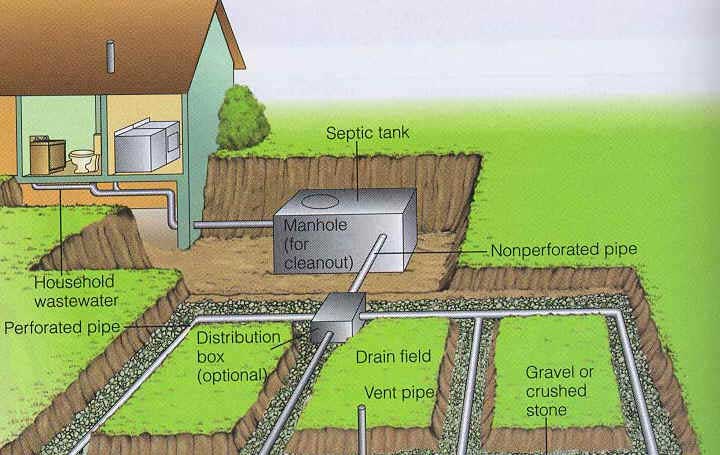

SDGS uses gravity only to transport wastewater, similar to conventional sewers. However, small diameter gravity sewers are always preceded by an interceptor tank for pretreatment of wastewater. The settling of solids occurs in the interceptor tank eliminates much of the suspended solid matter from the wastewater. Hence, there is no need to maintain self cleansing velocity in the sewers. This enables the collection systems to have smaller diameter pipes flowing full and at more flat slope. The pipes used are made of light weight plastic (PVC or HDPE) and can be buried at a relatively shallow depth. Manholes are not required for SDGS as there is no need for cleaning; instead, clean out ports are provided to maintain collection pipes.

Operation and maintenance costs for SDGS are very low comparing to that of conventional gravity systems. The only maintenance requirement is the periodic pumping septage out of the interceptor tanks, which is usually done every two to three years with the help of vacuum operated trucks or carts by the maintenance agency. Pumping out septage from the interceptor tanks can be staggered throughout using one or two vacuum trucks by emptying few tanks only per day.

Interceptor Tanks

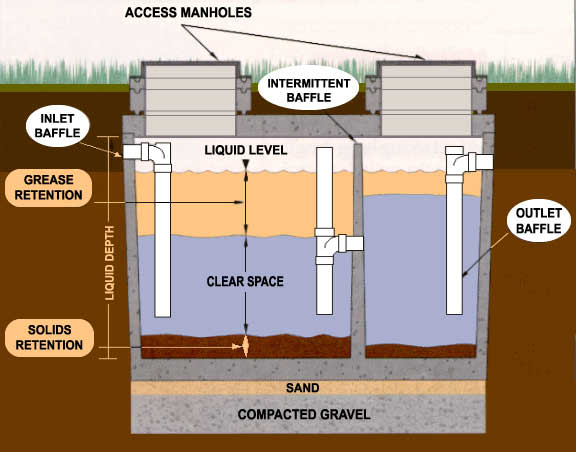

The design requirements of the interceptor tank include the following;

- Interceptor tank (preferably with two compartments) can be one for individual house or for number of houses (up to 4 houses).

- The design wastewater flow, is based on the water requirements of the population at the end of design period.

- The pipe connecting the toilet and the interceptor tank should be at least 100 mm in diameter, laid as straight as possible, and have a steeper slope than 1 in 30.

- The system requires ventilation. Vents may have to be located next to the building connected to the pipe leading to the interceptor tank. It should be tall enough to disperse foul-smelling gases.

- One day’s storage capacity in the tank allows sufficient retention time of wastewater. This minimizes surges and reduces the maximum peak flow that the sewers have to handle.

- A tee on the inlet side of the tank dissipates the energy of the wastewater as it enters and prevents short-circuiting.

- The outlet from the interceptor tank should be located about 75 mm below the level of the inlet. The outlet with a tee and an effluent filter prevents even finer solids from leaving the tank.

- The tank cover should be airtight to prevent escaping of odour and entering of storm water into the tank. But it must be provided with a manhole allowing access for desludging. Settled Sewer.

- PVC pipes can be used for the sewers as they have a very smooth inner surface, so that the effluent flows through them easily.

- The task of design of the system is simpler than conventional sewerage system because the pipes need not have to be designed for maintaining the self-cleansing velocity as there is no solids in suspension and there is no need for constant gradient between manholes.

- SDGS can be curved around any obstruction, can have a variable gradient, one that parallel to the ground surface. This results in a minimum of excavations to install.Pipes can be installed uphill over short distance.

It is important to check the difference in elevation between the interceptor tank and the sewer. If the tank is below the level of the sewer, wastewater will back flow into the interceptor tank.

- Manholes (Inspection chambers) of smaller in dimensions are required only at major junctions.

- Clean outs made from standard pipe – fittings can be installed at high points of the sewer. A typical clean out (right) and simple junction without a clean out (left) of SDGS

- There must be an overall fall from the upstream end of the sewer to its downstream end.

- The sewer is divided into sections over which the flow is of the same type (i.e. open channel or pressure flow) and reasonably uniform (i.e. the sewer can be laid at a more or less constant gradient).

5 Responses to “Small Diameter Gravity Sewers”

Leave a Reply

LIKE TO GET UPDATES

LIKE TO GET UPDATES  TO GET EXPERT GUIDE

TO GET EXPERT GUIDE

Really nice post for Small Diameter Gravity Sewers , I added your blog onto my favorite book reader.

Thanks Lot

This is really useful for Water Treatment based jobs. Much Appreciated.

Thanks..

It is useful for my lecture… I add your blog http://www.thewatertreatments.com in my presentation slide

Excellent!

I am compiling a policy document propagating adoption of a similar system in defense establishments which generally are sparsely populated.

I was thinking on lines of low pressure sewers ahead of the septic tank to transport the liquid waste to the STP. The pump may be run on solar power with a small holding capacity of say 2 hrs adjacent to the septic tank.

Could I seek your guidance?

This particular webpage is actually interesting on http://www.thewatertreatments.com. I have been fighting small leaking within my roof and also figured out the problem. They recommended that the right sealant is actually the silicone self …