Sequential Batch Reactor (SBR)

The Sequential Batch Reactor (SBR) is a variation of the ASP. As a fill and draw or batch process, all biological water treatment phases occur in a single tank. This differs from the conventional flow through activated sludge process, which requires separate tanks for aeration water treatment and sedimentation water treatment.

SBR systems contain either two or more reactor tanks that are operated in parallel, or one equalization tank and one reactor tank. The type of tank used depends on the wastewater flow characteristics (e.g. high or low volume).

These units are normally installed in situations where there is no public sewer and where a septic tank is not environmentally acceptable. The SBR treats the effluents to a very high standard (normally to 15 mg/ L suspended solids and 10 mg/ L BOD) which is suitable for discharging directly into a watercourse. It overcomes several of the common problems associated with packaged domestic sewage treatment units.

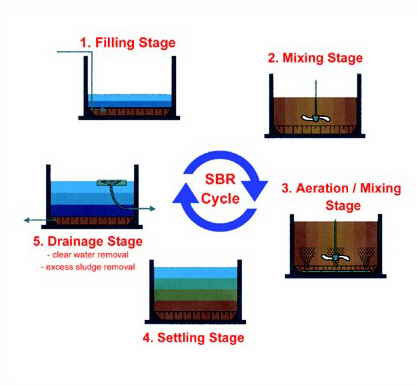

There are normally five phases in the SBR treatment cycle:

- Fill,

- React,

- Settle,

- Decant,

- and Idle.

The following are the SBR processes taking place in different phases:

- In the fill phase, raw wastewater enters the basin, where it is mixed with settled biomass from the previous cycle. Some aeration may occur during this phase.

- Then, in the react phase, the basin is aerated, allowing oxidation and nitrification to occur.

- During the settling phase, aeration and mixing are suspended and the solids are allowed to settle.

- The treated wastewater is then discharged from the basin in the decant phase. In the final phase, the basin is idle as it waits for the start of the next cycle.

- During this time, part of the solids are removed from the basin and disposed of as waste sludge.

Advantages of SBR :

- High effluent quality; reduces main pollutants including ammonia by 96%, and reduces phosphates by 88%

- SBR operates on a storage and batching system – storing the effluent at peak times in the PST and treating it in small batches throughout the rest of the day – thereby ensuring that each batch receives the full treatment time. Batch system eliminates peak surges

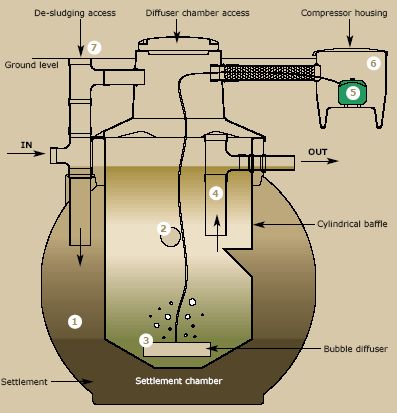

- There are no moving parts or electrical components within the tank. All functions within the tank are operated by air power generated by a small compressor/ blower.

- Process is simplified. Since all the unit processes are operated in a single tank; final sedimentation tank and return activated sludge pumping are not required,Compact facility; Operation is flexible; nutrient removal can be accomplished by operational changes, Quiescent settling enhances solid separation (low effluent SS), Systems require less space (small foot print) than extended aeration plants-of equal capacity. The system allows for automatic and positive control of mixed liquor suspended solids (MLSS) concentration and solids retention time (SRT) through the use of sludge wasting.

Disadvantages of SBR:

- High peal flow can disrupt operation unless accounted for in design,

- Batch discharge may require equalization prior to disinfection,

- Higher maintenance skills required for instruments, monitoring devices, and automatic valves

- It is hard to adjust the cycle times for small communities.

- Sludge must be disposed frequently.

- Specific energy consumption is high.

7 Responses to “Sequential Batch Reactor (SBR)”

Leave a Reply

LIKE TO GET UPDATES

LIKE TO GET UPDATES  TO GET EXPERT GUIDE

TO GET EXPERT GUIDE

I want to know whether SBR Tech is same as C-Tech (Cyclic Activated Sludge Process). Is there any SBR plant in India operating at Municipal Corporation level? What would be the problems the Municipal Corporation will phase in maintaining the SBR plants around 100 MLD?

Early reply will be appreciated.

Thanks,

Chamkaur Singh

we are contemplating the development of a 600-700 unit apartment complex which will require onsite wastewater treatment. I would like to know the pros & cons of an SBR vs a conventional disposal system.

معرفی مهندسین مشاور که sbrکار کرده باشند.

David Pawlaczyk, an sbr system takes half the room for a drain field area, has no odor, keeps our environment healthy, and will even allow you to recycle the water for all non potable uses, even to help heat and cool your buildings, (with the right HVAC system). It is all together the right thing to do, this is what I do, design and build SBR WWTPlants, nothing else compares.

If the number of decantation for SBR type will increase what does it mean? please help.

how to calculate the sequencing batch

Dear danny.

i agree SBR is one of superior model but if automation fails everything fails in an SBR plant i would suggest david pawlaczyk for a MBBR plant for his condominium with continuous flow…