Construction of Waste Stablization Ponds

1.Site Selection for Waste Stabilization Ponds.

The site selection for locating Waste Stabilization Ponds system should consider the following factors:

- The area where the water table is deep and the soil composition is heavy and impermeable.

- Silt or clay soiis are ideal for pond foundations and construction as that won’t allow the

- wastewater to quickly percolate down through the lagoon bottom to the groundwater.

- Building ponds over coarse sands, gravels, fractured rock or other materials, that will allow effluent to seep out of the pond or allow groundwater to enter in, should be avoided. Lagoons must be artificially lined with clay, bentonite, LOPE sheets, concrete, or other materials to prevent groundwater pollution.

- No part of the system to be within 200 m (preferably 500m) of any dwelling house. Facultative ponds and anaerobic ponds should be located at least 200 wand 500 m respectively away from the residential areas.

- Lagoons also should be located downgrade and downwind from the homes they serve, when possible, to avoid the extra cost of pumping the wastewater uphill.

- If possible, ponds should be sited downwind from dwellings, roads and other public places.

- The amount and predominant direction of wind at the site is another important factor, and helps to determine the lagoon’s exact position.

- Any obstructions to wind or sunlight, such as trees or surrounding hillsides must be considered Trees and weed growth around lagoons should be controlled for the same reasons.

- Soil must be suitable for pond stability.

- Surface drainage or storm runoff should be kept out of lagoons, if necessary diversion terraces or drains should be installed above the site.

- The pond system including inlet and outlet arrangements should be located above the probable maximum flood level M that area

The following are general considerations when siting a pond:

- Allowing for a straight run of pipelines, tractors and De sludging vehicles to the ponds.

- To minimize earthworks, site should be flat or gently sloping.

- Siting in an open area so as to take advantage of the sun and wind, which assist the efficient

- operation of the facultative pond and thus improve the quality of the pond effluent.

- If soil is permeable (>10 m/s), a plastic membrane plastic may be used to line the pond.

- Keeping systems away from overhead or underground power lines, water lines etc.,

- Avoiding sites that are likely to flood, have steep slopes that run towards a waterway, spring or bore hole, are pipe drained or mole ploughed, are likely to freeze over, or have recently been cleared of trees or similarly disturbed.

- Constructing the system below the effluent elevation so that gravity can be used to carry the effluent·

- Orientating the longest diagonal dimension of the pond parallel to the direction of the prevailing wind.

- Ponds should not be located within 2 km of airports, as any birds attracted to the ponds may constitute a risk to air navigation.

Geotechnical and/or hydro-geological explorations : Geological Technical Department aspects, if not taken into consideration, may cause the Waste stabilization ponds system to malfunction. A Geological technical Department site investigation should be made during the design stage to ensure correct embankment design and to determine whether the soil is sufficiently permeable to require the pond to be lined. A stable and impermeable embankment core shall be formed, whether chosen from an available local or imported soil After compaction, the soil should have a coefficient of permeability of 10-‘ m/s. Embankments must be well constructed to prevent seepage, excessive settlement and erosion over time.

- Appropriate sub-surface geotechnical and/or hydro-geological explorations should be undertaken to establish the suitability of proposed materials to meet anticipated conditions.

- Generally a minimum of 3 test holes per site or 1 test hole per 2 hectares (whichever is greater) should be made to establish soil conditions at the lagoon site.

- More test holes may be required if complex geological conditions are encountered or tithe site is located in an environmentally sensitive area.

- All test holes should be taken to at least 4 m below lagoon floor dry alien,

- Groundwater information below the lagoon site including water quality, water levels, direction of flow and gradient may be required for establishing lining requirements and monitor well requirements and locations if these are required.

- Lagoon cells should be relatively impermeable in accordance with the needs for functional treatment and protection of surrounding land and ground water.

- As an example, seepage from a lagoon facility should not exceed 15 cm per year.

- It is recommended that field and/or laboratory tests be carried out to establish the hydraulic conductivities of soils at the lagoon site and any proposed soil lining materials.

- At least one hydraulic conductivity test per 2 hectares of lagoon area should be carried out. For in-situ materials or soil liners an on-site permeability of 10 times the laboratory value should be used to calculate seepage tosses.

- Adequate provisions for monitoring and for seepage control measures such as cutoffs, subsurface drainage interceptors, etc should be considered.

- Pre-filling the pond(s) or other techniques should be considered in order to protect the liner, prevent weed growth and to protect against desiccation of the seal material.

2. Size and Shape

The exact dimensions of lagoons vary depending on the type of processes they use for treatment, the amount of waste water that needs lobe treated, the climate, and whether other lagoons or other types of treatment are also being used.

- The size and shape of lagoons is designed to maximize the amount of time the wastewater stays in the lagoon.

- Detention time is usually the most important factor in treatment.

- The size and shape of lagoons is designed to maximize the amount of time the waste water stays in the lagoon.

- Detention time is usually the most important factor in treatment. The pond can be oval, square, rectangular or polygonal depending upon site contours. In case of rectangular ponds, it is common to have length approximately equal to three times the width.

- Faculative and Maturation ponds can have L. B ratio of 10 : 1;

- The ponds should be rounded off at the corners in order to minimize the accumulation of floating materials and creation of idle corners.

- The shape should facilitate full detention period for the in fluent as designed and to locate inlet and outlet accordingly.

- Keeping the corners of lagoons rounded also helps to maintain the overall hydraulic pattern in the lagoons and prevents dead spots in the flow, called short-circuiting, which can affect treatment.

- In systems that have embankments separating pond cells, embankment also should be easy to maintain. Interior embankment slopes are determined by the size and depth of the lagoon, potential wave action and other factors.

- The pond area should be cleared of all vegetation and debris. The pond bottom should be made as level as possible A tolerance of ±10 cm in the finished pond bottom could be permitted from the designed bottom level.

- Where excessive percolation is anticipated as in the case of limestone, sealing of pond bottom with a blanket of clayey soil or other suitable material should be considered. Facultative lagoons are usually 1.0 to 15 us deep, so they have enough surface area to support the algae growth needed.

Embankments:

- Embankments or dykes should be constructed with the top width should be at least 3 m to permit access for maintenance vehicles.

- For small ponds (up 10 0.5 Ha area) top width of embankment may be 1.5m.

- Side slopes of dykes should be stable. In general, interior side slopes may be 2 – 3 1 when the face is unprotected. Steeper slopes of 1 – 15 1 may be used when soil is suitable and the face is protected with full pitching using stone riprap, precast cement concrete slabs or other suitable means of erosion control.

- External slopes of the embankment should be 2.0 – 3.0 1. External slopes should be protected from storm water erosion by providing adequate drainage.

- The moderate outer slope makes the banks easier to mow and maintain.

- Seeding of slopes with grass is encouraged; a slow growing rhizomatous species should be used to minimize maintenance.

- Freeboard should be a minimum of 1 m except for very small ponds where 05 m may be considered.

Waste Stabilization Ponds Inlets:

- Influent pipe lines should be installed using materials and construction methods which are generally accepted for underground sewer construction with due consideration for the quality of waste water.

- In case the pond cell is large, multiple inlets should be provided along the inlet side of the pond at the rate of one for every 0.5 to 1.0 ha of pond area.

- Inlets should be extended into the pond for one-third to one-fourth the pond length or 15 to 20 m, whichever is less.

- The invert of the last manhole on a gravity outfall line should heat least 15 cm above the design operating water level of the lagoon.

- A concrete apron of adequate size not less than 1.2 m x 1.2 m should be provided under discharge to prevent erosion of pond bottom.

- Pressure mains terminating ma sewage lagoon should be fitted with a valve immediately upstream of the lagoon.

- In fluent should be mixed into the main body of the pond to avoid localized overloading, taking into consideration not to create short-circuiting.

- Inlet position and type has a significant impact on treatment efficiency in ponds.

- Dropping inlets from horizontal pipes above the water have similar behavior as submerged horizontal inlets.

- For high-load waste waters, horizontal inlets may be needed to mix wastewater into the pond.

- For low-load waste waters, consider a manifold or baffled vertical inlet but only after consideration of wind influences.

- Inlet positioning has a major influence on the flow pattern.Designers need to consider the

effect of inlet position in conjunction with outlet position and pond shape.

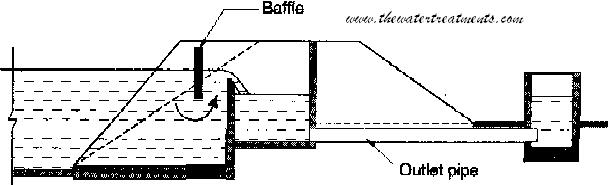

Waste Stabilization Ponds Outlets:

- Multiple outlets are desirable except in small ponds and may be provided at the same rate as for inlets.

- The outlet structures may be with weir boxes and hanging baffles submerged into water to ensure that floating algal scum is retained and to facilitate 0th M.

- Outlets should be placed octal the main flow path of the incoming waste water (close into a corner).

- Final outlet positioning can be selected after the inlet position/type and pond/ baffling have been designed.

- Outlet manifolds are not recommended.

- Long evenly spaced baffles improve pond perfomunce. Baffles of 70% width gave superior performance compared with 50% and 90% width.

- Horizontal baffles were found tube more efficient than vertical baffles.

- Longitudinal baffling was found tube not efficient than transverse baffling.

- Localizing baffles rinse to horizontal (but not other types!) inlets is generally effective.

- A minimum of two baffles in a pond is recommended. A further improvement was achieved using four baffles and this extra cost may be warranted in some cases and more than four baffles would not be recommended.

- Baffles that shield the outlet are beneficial.

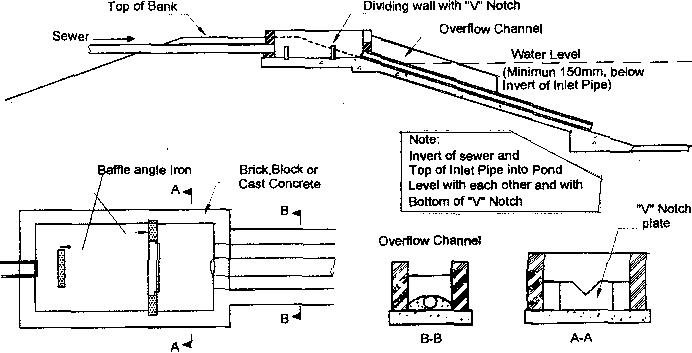

Flow measuring devices

It is desirable to provide flow measurement devices for inflow and outflow. Without influent flow measurements it is impossible to determine the loading of a pond system, and without effluent flow measurements it is impossible to determine the percolation and evaporation losses. A simple V-notch or parshall flume or a weir is quite common.

Waste Stabilization Ponds interconnections:

Transfer (intercormecting) and discharge piping should allow flexibility of operation, be positioned to avoid short-circuiting, be adequately sized of suitable material and equipped with appropriate controls.

- Overflow conduits should be provideibbetween cells, but provision of emergency overflows which permit uncontrolled discharge out of the lagoon is discouraged.

- Upstream end of the interconnection pipe should be submerged about 25cm below the water level. The down stream ends may be provided with a bend facing downward to avoid short circuiting. Care must be taken to prevent erosion of embankment

- Where practical, weirs should be provided in the outlet chambers for flow measurement.

Waste Stabilization Ponds Protective measures:

- The complete WSP area should be enclosed with an adequate fence to prevent entering of livestock and to discourage trespassing.

- A vehicle access gate of sufficient width to accommodate all equipment should be provided. Access gates shou/d be provided with locks.

- Fences should be located away from the outside toe of the dyke to facilitate dyke mowing and maintenance operations.

- Appropriate warning signs should be provided along the fence to designate the nature of the facility and against trespassing.

Waste Stabilization Ponds Construction Aspects

- During construction of a WSP system, the following considerations should be made:

- Since the principal construction activity is earthmoving and there should be a good balance between cut and fill.

- Embankments should be made from the local soil compacted in 250 mm thick layers to 90 percent of its maximum dry density, such that its coefficient of permeability is less than 10′ m/s.

- Pond lining, if required, is normally a plastic membrane covering the entire pond base and the embankments. Membrane joints need to be watertight Alternatively the ponds can be sealed with a 250 mm thick layer of clay.

2 Responses to “Construction of Waste Stablization Ponds”

Leave a Reply

LIKE TO GET UPDATES

LIKE TO GET UPDATES  TO GET EXPERT GUIDE

TO GET EXPERT GUIDE

Hi

I am looking for an operating and maintenance costs for an rock filter constructed at one corner of an pond. The pond is 1.6m deep and the volume of rock installed is circa 500 cum.Cost to inlcude the removal, cleaning of the algal matter on the surface and laying back to its position.

Thanks in advance.

Sorry we are the educational and consulting development of water treatment and its related fields only.

Informative and so helpful