Mechanical Aerator

Type of Mechanical Aerators

Mechanical aerators are of two general types; surface aerators and turbine aerators.

- Surface aerators consist of submerged or partially submerged impellers, which are centrally mounted in the aeration tank. Surface aerators agitate the wastewater vigorously, entraining air in the wastewater and causing a rapid change of the air-water interface to facilitate solution of the air. Another type of surface aerator consists of a paddle wheel or brush, partly submerged in the wastewater, revolving on a horizontal axis. Air is absorbed by surface contact and by droplets of water thrown through the air by the paddle mechanism.

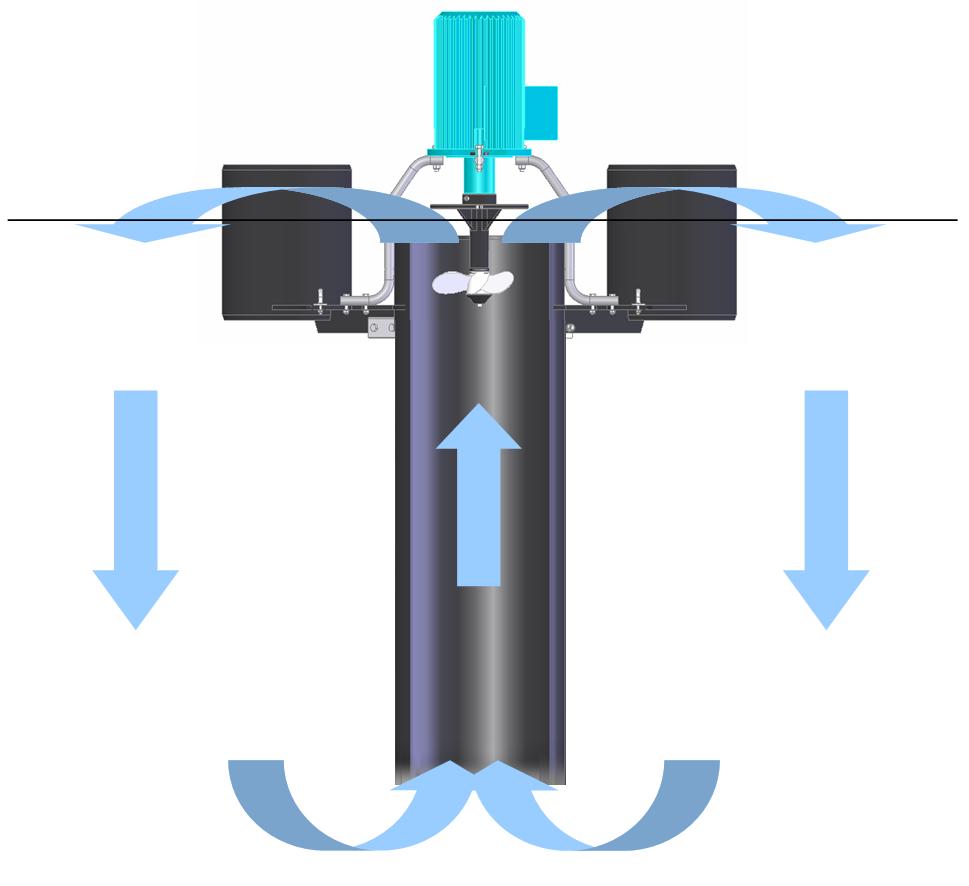

- Turbine aerators are usually upflow types that rely on violent agitation of the surface and air entrainment for their efficiency. A draft tube may be utilized to control the flow pattern of the circulating liquid within the aeration tank. The draft tube is a cylinder with flared ends mounted concentrically with the impeller, and extending from just above the floor of the aeration tank to just beneath the impeller.

Oxygen-transfer rate of mechanical aerators

Surface aerators are rated in terms of their oxygen-transfer rate or kg of oxygen per kW-hour (kW-hr) at standard conditions. Surface aerators normally have an oxygen transfer efficiency of 1.2 to 2.4 kg 02/kW-hr while turbine aerators have oxygen transfer efficiency of 2 to 3 kg. 02/kW-hr.

Aeration period

In the ASP, the sludge accomplishes the major part of the removal of BOD from the wastewater being treated in a relatively short period of aeration. It takes, however, a much longer time for the sludge to assimilate the organic matter which it has absorbed. During this time an aerobic environment must be maintained. To effect the most complete treatment of wastewater and the most economical operation in the conventional ASP, an aeration time of 6 to 8 hours has been found to be adequate for diffused air aeration and 9 to 12 hours for mechanical aeration. Substantially shorter periods are used in some of the modifications of the conventional process. These shorter aeration periods generally result in a lowering of the quality of the plant effluents.

Surface Aerator with vertical axis

Surface aerators consist of partially submerged impellers that are attached to motors mounted on floats or on fixed structures. The impellers are fabricated from steel, cast iron, non-corrosive alloys and FRP, and are used to agitate the wastewater vigourously, entraining air in the wastewater and causing a rapid change in the air-water interface to facilitate solution of the air

Surface aerators are commonly used for completely mixing tank to provide high mixing intensity. For the aeration basins deeper than 4.5 m, draft tube or auxiliary submerged mixing impeller must be installed. DO is the highest near the impeller blade and decrease as the fluid flows back below the surface of aeration tank toward the aerator.

Surface Aerators with Horizontal axis

The mechanical surface aerator with horizontal axis is patterned after the original Kessener brush aerator, a device used to provide aeration and circulation in oxidation ditches. The brush type aerator had a horizontal cylinder with bristles mounted just above the water surface. The bristles were submerged in the wastewater and the cylinder was rotated by an electric motor drive, spraying wastewater across the tank. Angle steel or plastic bars or blades are now used instead of bristles.

Submerged turbine aerators

In submerged mechanical aerators air or pure oxygen may also be introduced by diffusers into the wastewater beneath the impeller. The impeller is used to disperse the air bubbles and mix the tank contents. A draft tube may be used with either up flow or down flow models to control the pattern of the circulating fluid. Submerged mechanical aerators are available in sizes from 0.75 to 100 kW and are commonly used for completely mixing tank. They provide high oxygen transfer rate, up to 100 mg/ L/ h. The effective aerating area is ranging from 4 to12.5 m2/ kW

4 Responses to “Mechanical Aerator”

Leave a Reply

LIKE TO GET UPDATES

LIKE TO GET UPDATES  TO GET EXPERT GUIDE

TO GET EXPERT GUIDE

I have Ph.D in Civil Engineering/Sanitary Engineering and found your Website helpful and rich with scientific information for the proffesional engineer ( design,execution and maintenance) thank u alot

I FOUND YOUR WEBSITE VERY USEFUL. I AM A WATER ENGINEER, WORKING WITH DHARMATTAN NIGERIA LIMITED. PLEASE, I NEED DETAIL INFORMATION ON HOW TO WASH, CLEAN AND SERVICE AERATOR. THANKS

I am Civil Engineer from the US. Nigeria homes have individual sewages. Now, what chemicals can I use to treat these individual sewages on sit?

Dear sir,

We wish to import mechanical water areaters to my2 acares shrimp ponds,

My pond size 200 mtrsx100 mtrs,

So pl send quotationn for same. along with how many units we need etc,

Regads,

swamy